GYRO

SERVICES

GETS is providing Multi-shot gyro service to its clients both off-shore and on-shore in the Iran drilling market

Since spreading the use of directional drilling in the oil and gas industry, the limitation of the Magnetic Interface in MWD readings has been a great challenge. Gyro Surveying has solved this issue and now it is used in almost all directional drilling projects which face magnetic interface.

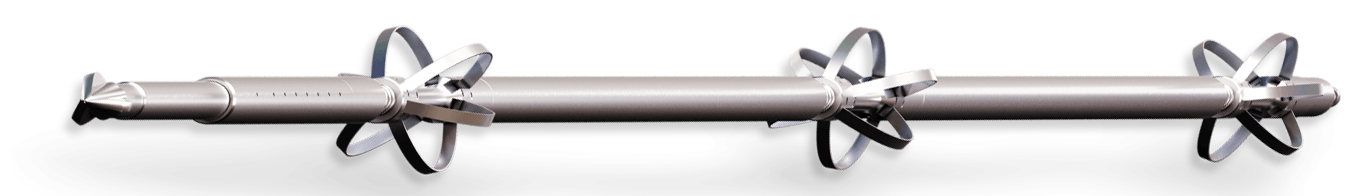

There are many types of downhole gyro surveying tools, but it is widely accepted that north-seeking tools are the most accurate systems in the market. It is not affected by magnetism and it is more accurate than reference and magnetic gyro technologies.

North seeking gyro benefits from gyroscopes and accelerometers to measure direction, inclination, and the tool face. Also, it has the advantage to be run in memory mode or via an electric line, which allows reading and data quality to be recorded in RT.

Before any job, the gyro tool will be tested, and if it is needed it will be calibrated as well to make sure the readings would be accurate. This calibration will help to precisely calculate the correct orientation of the tool and develop a well profile.

During surveying, several recordings from accelerometers and gyroscopes are averaged at each depth and the calculated final reading is sent through the wireline to the surface system. The surface system will apply the calibration data to compensate for temperature, etc.

GETS is providing Multi-shot gyro service to its clients both off-shore and on-shore in the Iran drilling market. The ongoing project is to develop our fleet with high-tech continuous gyro tools to answer our client's needs.