Bit Repair Service

A Method of Cost Saving

This service will deduct the cost spent on providing bits and will allow you to manage your expenditure wisely

With declining oil prices, operators are becoming more cost-conscious. In GETS, we have decided to help our customers achieve significant savings on their drilling costs by introducing the service of overhauling and refurbishing PDC drill bits.

Following rigorous care and inspections, we restore your used bits to their original status and guarantee comparable performance to that of the brand-new bit at a fraction of the cost.

Our International Partner

Approved by Cheveron

With our competent partner with a solid background in bit repairing, we will assure our clients with a high-quality repaired bit which are ready to perform as nearly close to a new bit!

Our partner has been approved by one of the biggest international oil and gas companies (Chevron) to repair their bits.

We can repair as many as 200 bits per year.

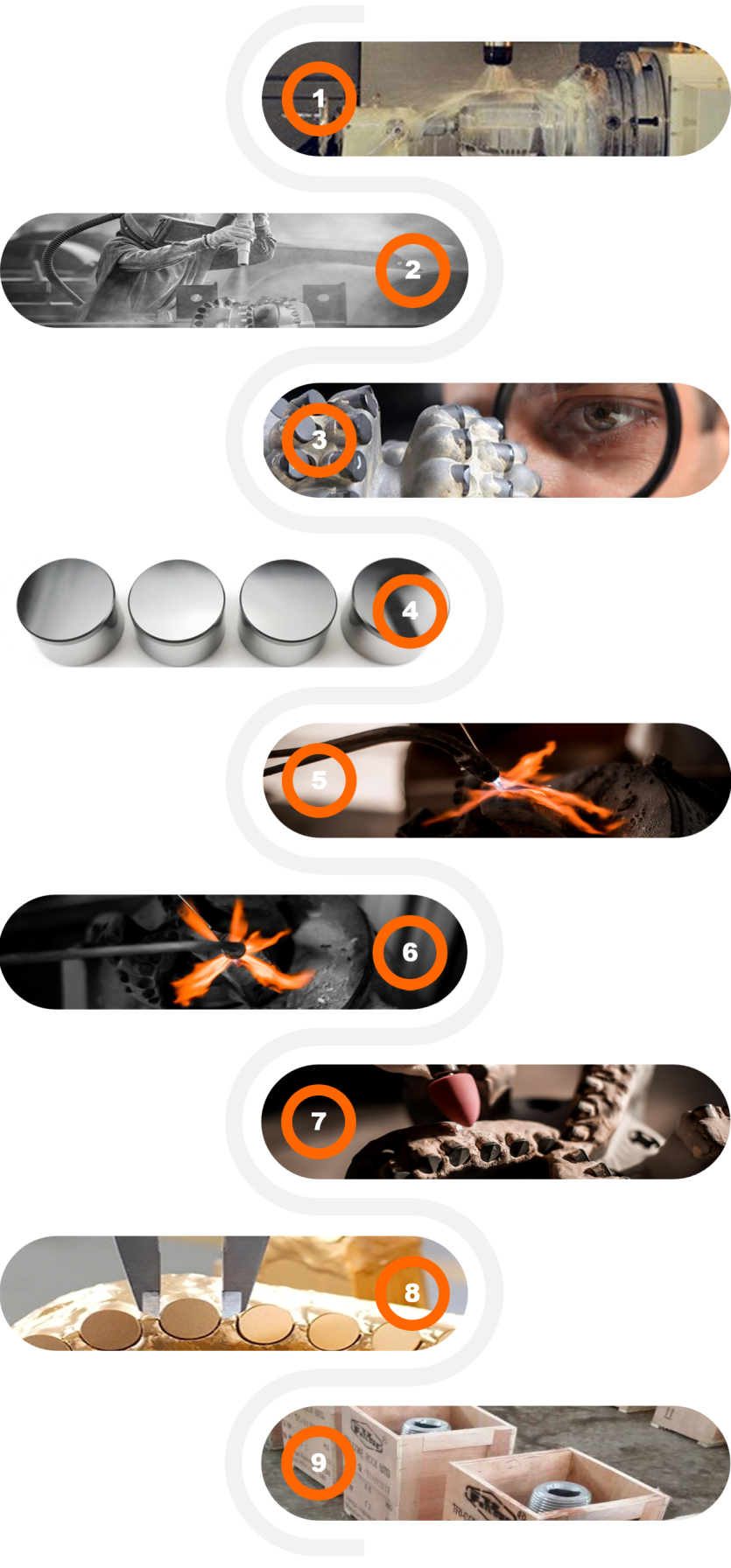

Bit Repair Process

Washing

Blasting

Pre-repair Inspection

Repair Plan

&

Cutter

Selection

Brazing

Post Repair

Inspection

Painting

&

Packing

Hard Facing

&

Cutter

Brazing

Grinding

The Duration of

Bit Repair Process

From the time client submits the call out for repairing a bit, we will check the nominated bit if it passes the requirement for being repaired or not. If the bit fit to be repaired, we will deliver the repaired bit in “30 days” in the client’s desired location.

The Duration of

Guarantee

We believe by following process in repairing bit, the repaired bit would be ready for operation. The result shows that the performance of repaired bit is the same to new bit. That is why we guarantee that our repaired bit will have 80% of the performance of new bit in “equal conditions”.