DESCALING INSTRUMENT

A Method of Cost Saving

Operators in the oil and gas industry need to reduce their costs to remain competitive and maximize economic recovery.

GETS’ challenge for operators is to reduce costs while improving safety and production efficiency.

Adopting the right cost reduction strategy now is key to survival and growth.Most companies are recently cutting their planned projects and budgets.This is called cost avoidance and this is a wrong cost reduction strategy.

GETS has implemented a unique proposal for Drilling contractors and Oil operators which not only reduces their cost but also, they can benefit from improved HSE results.

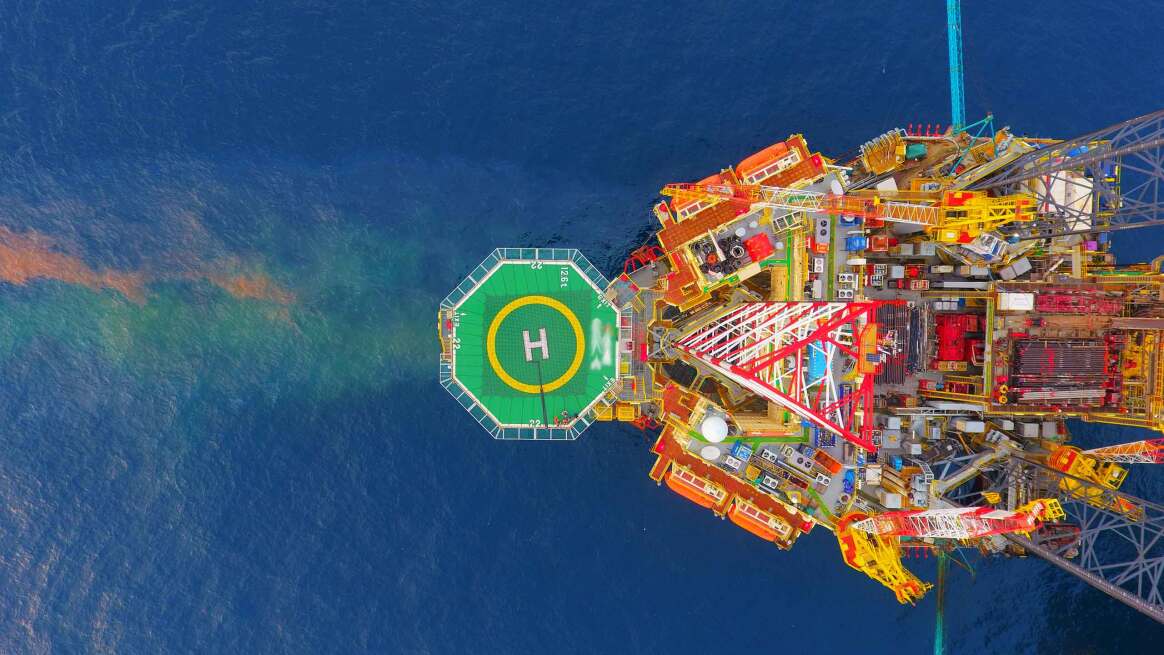

RIG CONDITION

ASSESSMENT

DEFENITION

Rig condition assessment provides adequate information about the condition of the rig. This is a survey normally carried out in a range of 7 to 30 days, based on the width and depth of inspections performed. The range of inspections also differs on a case-by-case basis. A minimal rig assessment survey will include corrosion monitoring, structural integrity, and CLASS requirements. A more thorough inspection will go into design optimization and improvement also and will take longer.

RIG CONDITION

ASSESSMENT

BENEFITS

The main benefit rig assessment provides, is the information about the condition of the Drilling rigs. This information can be processed to provide knowledge and improvement/mitigation possibilities. The other thing is the option for reducing costs, either in maintenance or HSE related. Downtimes and NPTs cost a lot and as the oil price is again getting high, every day lost is a huge money lost. Assessment provides the option to improve maintenance and reduction of downtimes.

1. In Commissioning Phase

OUR SERVICE

ADVANTAGES

With complete and thorough tests and inspections, we can ensure our clients that the drilling unit which is going to be hired meets their rental contract terms and specifications or not. Also, function testing, pressure testing, load testing, and insulation resistance checks for all critical equipment onboard the drilling unit, as applicable, will be conducted accompanied by a check that the proper safety devices are installed and are working correctly.

2. When going for a 5-year overhaul

With complete and thorough tests and inspections, we can ensure our clients that the drilling unit which is going to be hired meets their rental contract terms and specifications or not. Also, function testing, pressure testing, load testing, and insulation resistance checks for all critical equipment onboard the drilling unit, as applicable, will be conducted accompanied by a check that the proper safety devices are installed and are working correctly.

3. While Drilling Unit is Active

This inspection will cover an in-depth survey of the state of maintenance of the rig. It includes an inspection of all safety-critical elements of the installation and all equipment that could be anticipated to cause operational downtime when a mechanical failure of that equipment occurs.

We deliver an in-depth, risk-based technical report to equip you with a comprehensive evaluation of the condition and operability of equipment and systems.